Advantages

Inserts have a place in the industry; turning or milling, but there is a better way of drilling!

What are the advantages of using our high performance brazed carbide lug hole drills, valve hole drills, rear valve hole drills, and tinnerman drills over indexable or solid carbide drills?

-

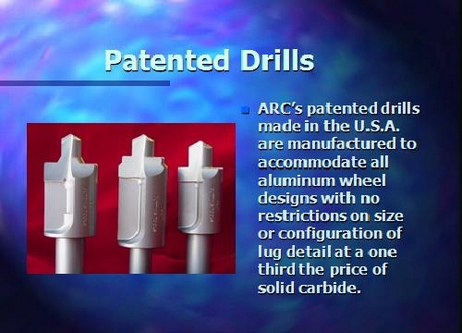

1/3 the cost per-drill over indexable or solid carbide

-

Most cost effective process of drilling = less than $.01 per hole

-

No restrictions on size or configuration of complex forms

-

Capable of drilling all grades of aluminum, even 6061 forged

-

Form is locked in on both flutes = 1/2 chip load

-

Ball seat radius held within +/- .0005 tolerance if needed

-

Conical seat held within 0°5' minute tolerance if needed

-

Better finishes while breaking all sharp edges

-

Burr control and burnished finish on work

-

A balanced drill for higher speeds and feed rates

-

One cycle pass, without pre-drilling work area

-

Improved chip evacuation for robotic applications

-

Small eyebrow chips which will not damage the finish on wheel

-

No small screws to mess with

-

No mixing up inserts when changing out tool

-

Easy loading into end mill or collect holder

-

Thru spindle coolant at a fraction of the cost

-

Unsurpassed tool life 55,000 to 75,000 cycles per run

-

Feed rates in excess of 100 IPM

-

Several resharpening to new condition at 1/3 the cost of new drill

-

Faster turnaround time for new or reconditioned drills

-

Less of a loss $$$ when you have a wreck or operator error